In today's fast-paced industrial landscape, the demand for high-quality components that ensure efficiency and reliability is paramount. Among these components, the electric bellows stop valve plays a critical role in fluid control systems across various applications. An Electric Bellows Stop Valve OEM (Original Equipment Manufacturer) manufacturer specializes in designing and producing these essential components, which are integral to many sectors, including chemical processing, water treatment, and HVAC systems. This article delves into the importance of electric bellows stop valves, the advantages of sourcing from an OEM manufacturer, and the key factors to consider when choosing one.

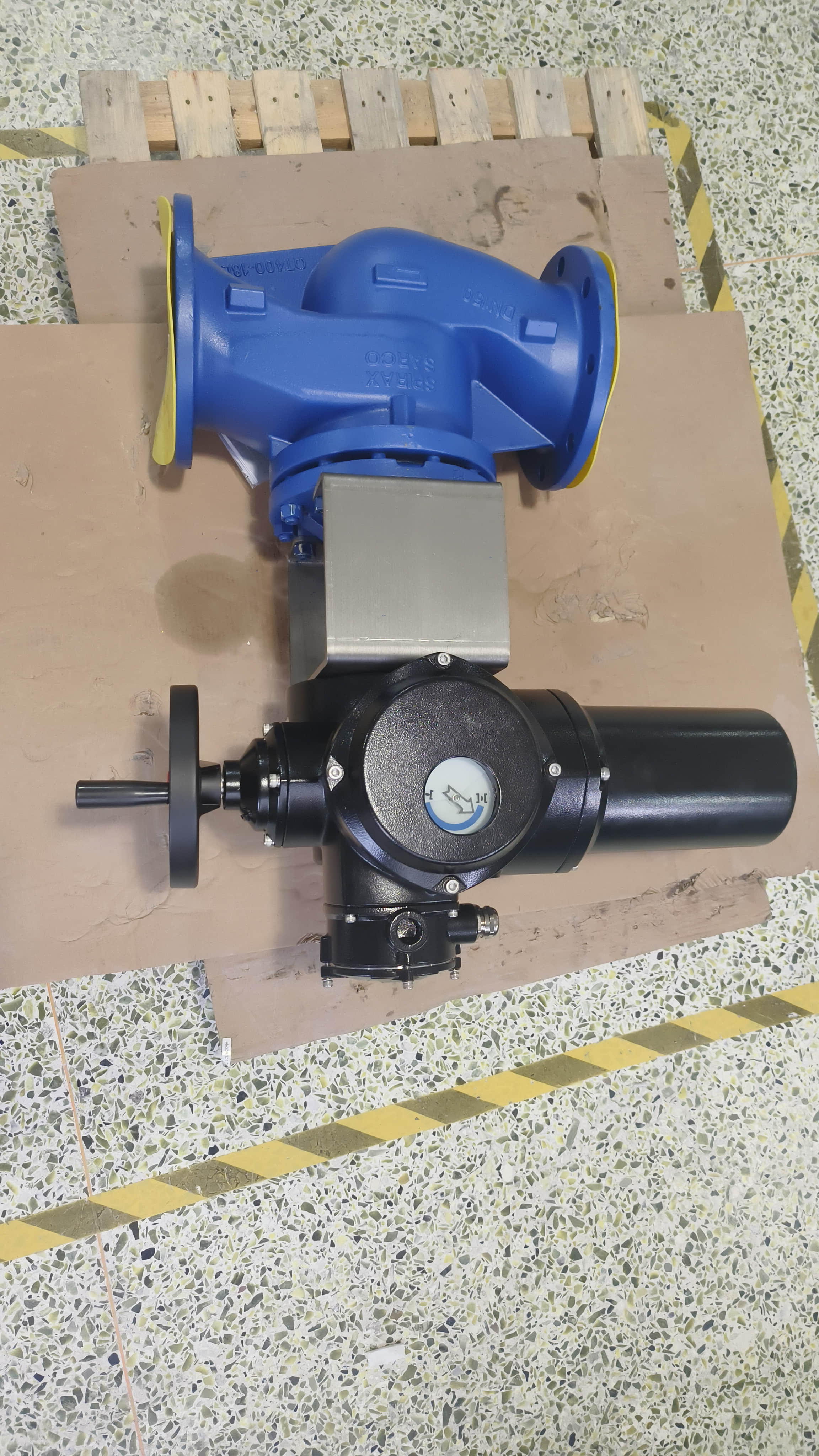

Understanding Electric Bellows Stop Valves