In today's rapidly evolving industrial landscape, the importance of efficient fluid control systems cannot be overstated. Among the various components used in these systems, pneumatic ball valves play a crucial role due to their reliability, precision, and ease of operation. For industries seeking high-quality pneumatic ball valves, the services of Original Design Manufacturers (ODM) have become indispensable. This article delves into the significance of pneumatic ball valve ODM manufacturers, their benefits, and their role in enhancing industrial operations.

Understanding Pneumatic Ball Valves

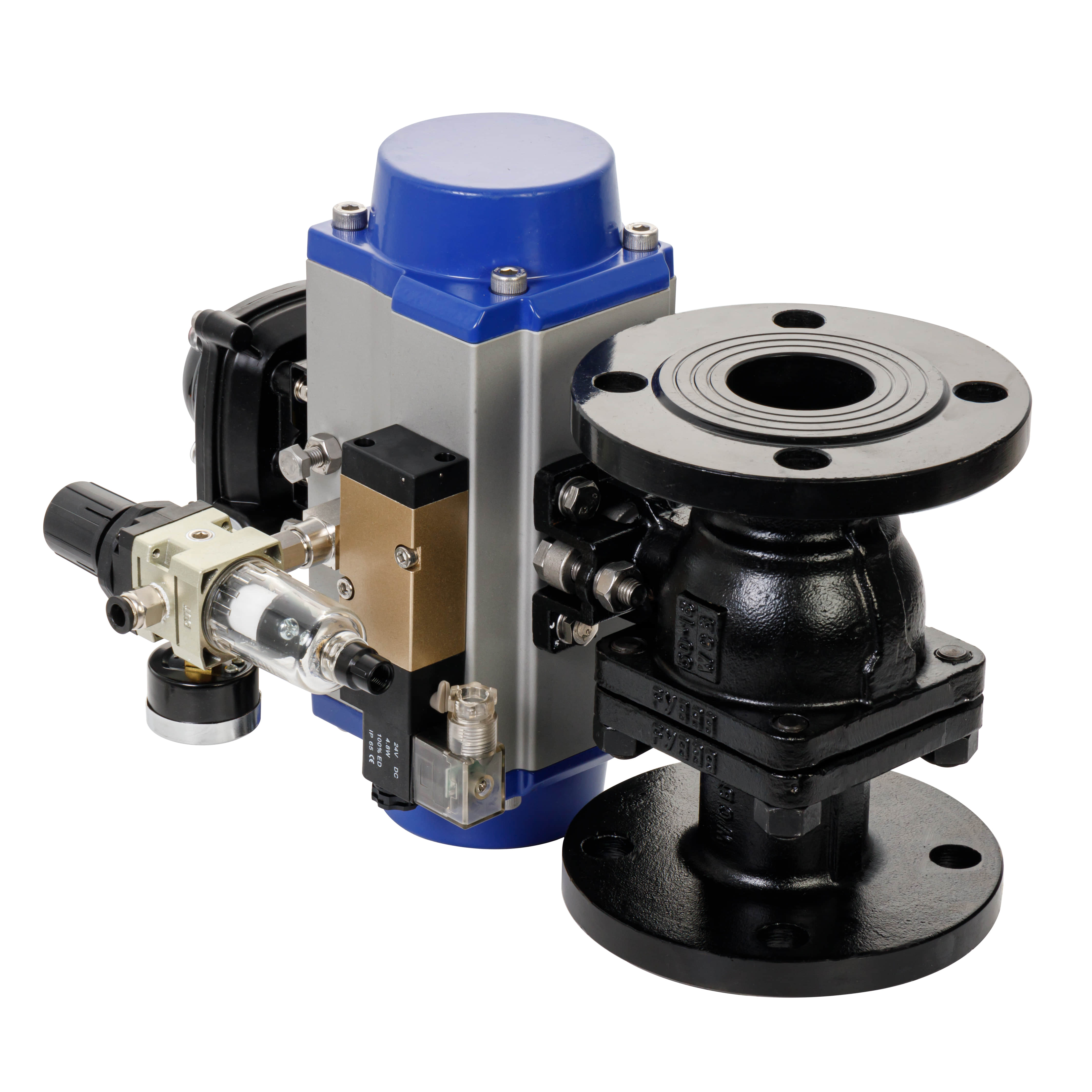

Pneumatic ball valves are automated devices that control the flow of gases and liquids in a piping system. These valves operate using pneumatic actuators, which utilize compressed air to open and close the valve. The design features a spherical disc (the ball) with a hole through its center. When the valve is open, the hole aligns with the pipe, allowing fluid to pass through; when closed, the ball rotates to block the flow. This mechanism ensures quick response times, precise flow control, and minimal pressure drop, making them ideal for various applications, including water treatment, chemical processing, and oil and gas.