In today's industrial landscape, efficient fluid control is a crucial aspect of numerous applications, ranging from power plants to chemical processing and water treatment. One of the key components that ensure smooth operations in these systems is the valve. Among the various types of valves, the electric bellows stop valve stands out for its reliable performance, durability, and precision in regulating fluid flow. As industries continue to demand high-quality, custom-designed solutions, the role of Electric Bellows Stop Valve OEM (Original Equipment Manufacturer) manufacturers has become increasingly important.

Understanding Electric Bellows Stop Valves

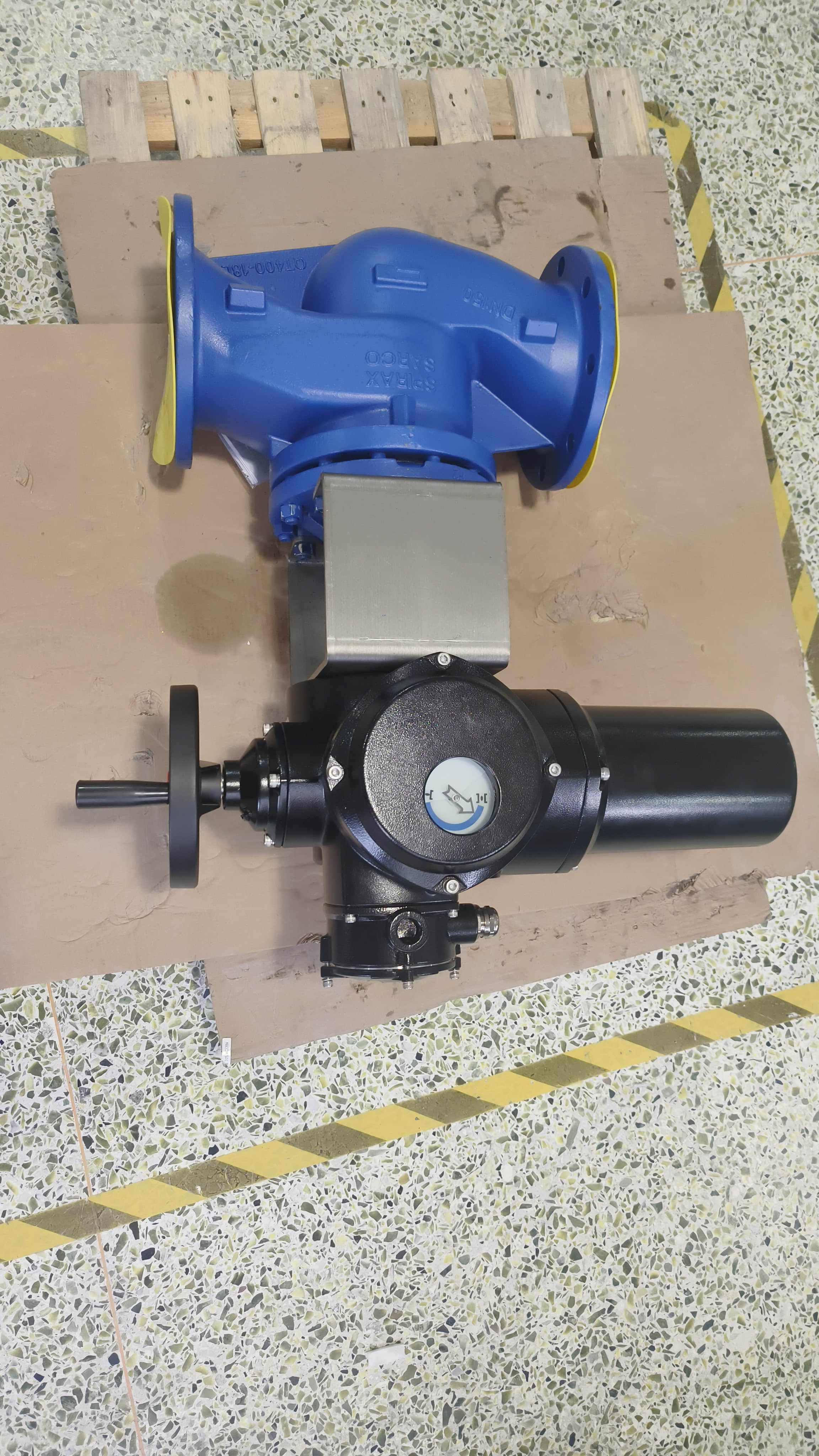

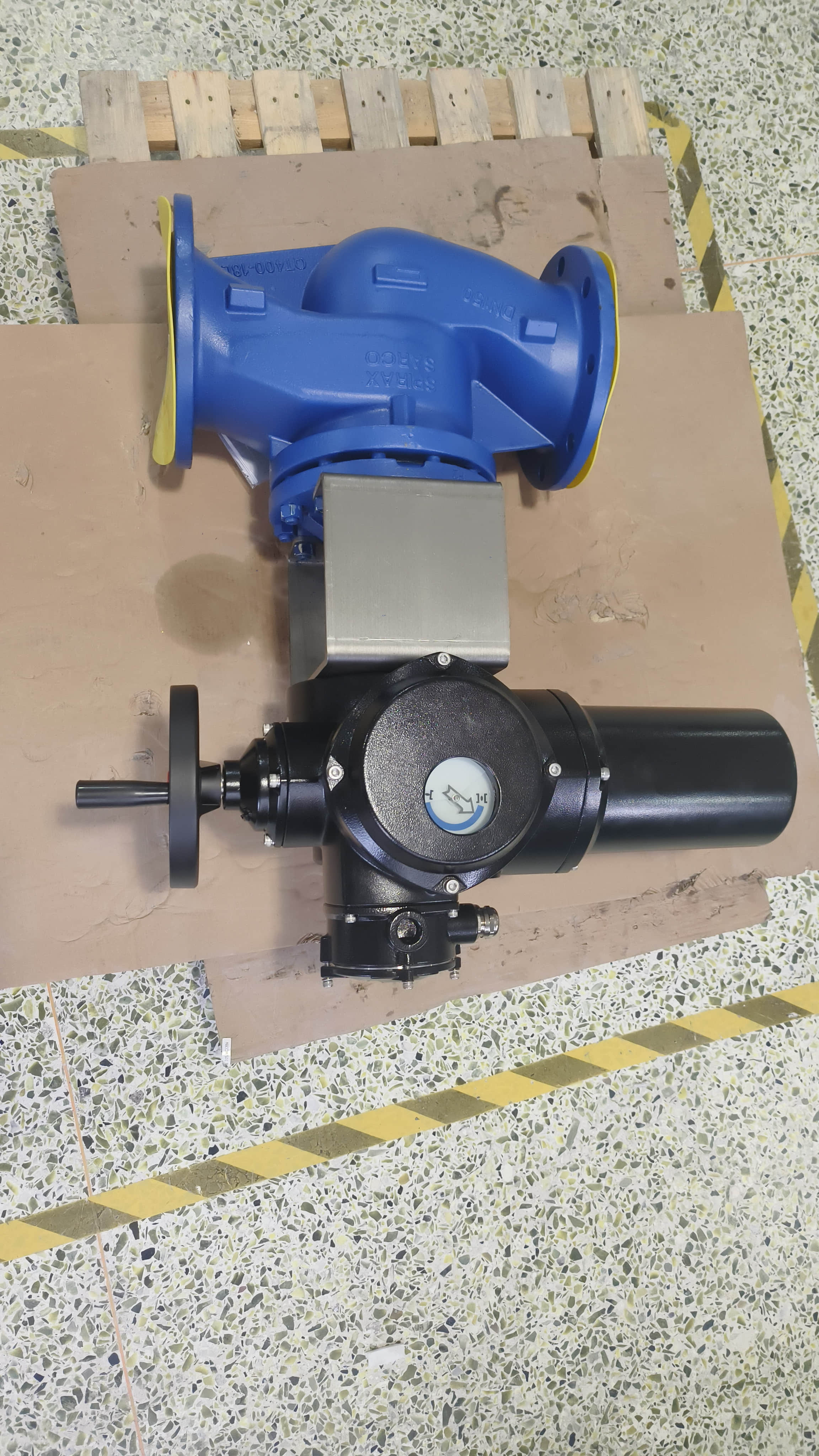

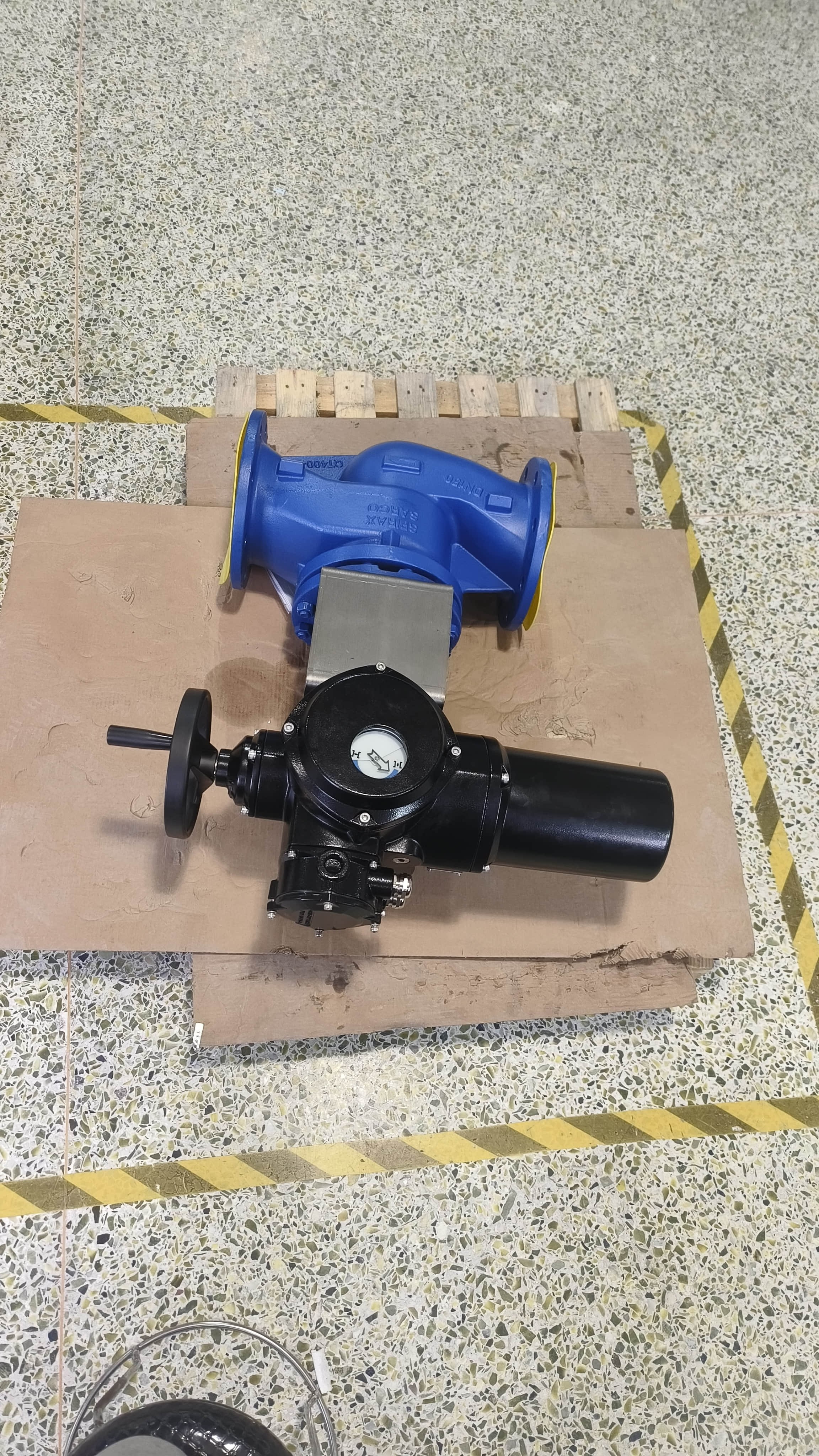

An electric bellows stop valve is a type of shut-off valve that combines the functionality of a traditional stop valve with the advanced control offered by electric actuators. The valve is typically used to control the flow of liquids or gases within a system, providing precise regulation. It is called a "bellows" valve because it uses a bellows—an accordion-like structure made from materials such as stainless steel or elastomers—located between the valve body and the actuator. The bellows serve a critical role in preventing leakage, ensuring a reliable seal even under high-pressure conditions.